Parameter

- Description

The KR1A、KR1 Instant Flat Rice Noodle(KWUi Tiew)Production Line of Kennyway is the famous advanced product in China and other countries!

After introduced many Lines of KR1, VIFON of Vietnam had also introduced 3 Lines of KR1A from Kennyway while many KR1A Lines introduced from Kennyway by Acecook Co. & Kenmin Co. of Japan, and President Rice Products Co. of Thailand.

The Flow Chart of KR1A:

rice→elevating by jet flow→sand separating→rice washing & soaking by jet flow→dehydrating→grinding→sifting→rice liquid storage→sheet steaming→rice sheet pre-drying→low temperature auto continuously hanging aging→auto sheet slitting & cutting→scaling & forming→drying→packing→product

Notes: The flow chart of KR1 is without "low temperature auto continuously hanging aging" process.

The technical data Of KR1A, KR1 Production Line:

| Type | Capacity (T/8H) | Total power (Kw) | Production Area (M2) | Minimum length of workshop (M) | Steam consumption (Kg/H) |

| KR1A-20 | 2.0 | ~125 | 1000 | 120 | 1500 |

| KR1A-30 | 3.0 | ~165 | 1200 | 140 | 2200 |

| KR1-10 | 1.0 | ~55 | 600 | 60 | 800 |

| KR1-15 | 1.5 | ~75 | 800 | 70 | 1200 |

| KR1-20 | 2.0 | ~85 | 950 | 90 | 1500 |

| KR1-30 | 3.0 | ~110 | 1100 | 100 | 2200 |

Viet Nam Food Industry Co., a successful example of adopting the Instant Flat Rice Noodle Production Line from Kennyway!

After introducing 5 Instant Flat Rice Noodle (Kwui Tiew) Production Lines from Kennyway, VIFON(Viet Nam food industries Co.) became one of the biggest enterprises in the field of processing instant flat (Kwui Tiew) rice noodle. In May 2002, VIFON awarded a golden medal & a certificate of merit to Mr. Cen Jun Jian, the general manager of Kennyway for his great help to VIFON. After 2005, VIFON introduced 3 KR5A Production Lines from Kennyway .

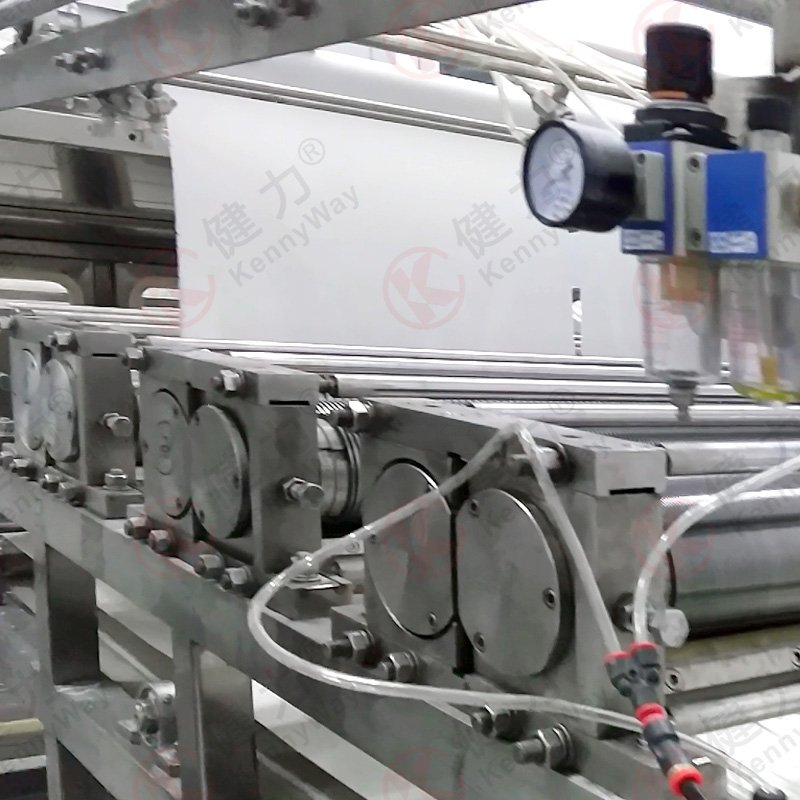

Continuous Sheet steamer:

1. It may use nylon or Teflon belt.

2. The thickness of sheet is controlled by stepless variable drive with inverter.

3. It is easy to install belt, clean and maintain with the cover elevator.

Sheet Pre-Dryer:

1. It is easy to clean without guides & chain by using Teflon mesh belt.

2. No friction pollution as the result of no chain & no guide.

3. Easy to separate the sheet from the Teflon mesh belt.

4. Easy to get perfect sheet & high rate of end product.

Low Temperature Hanging Aging Machine:

1. Shortened obviously aging time by low temperature(3℃~8℃) aging and carried out continuous production of the line.

2. To keep the moisture of rice sheet by moisteners and to get better effect of rice sheet aging.

3. The innovation design of automatic to change the pitch of two hanging rods. It makes the rice sheet continuous aging possible.

Slitting, Cutting & Conveying Machine:

1. Slitter & cutter made by SUS 304.

2. Using PVC belt.

3. Slitter with auto fog spray device.

Auto Press Shaper for noodle cakes :

1. Auto press shaper is an original patented product of Kennyway. It makes noodle cake packed possible by auto packing machine.

2. The press shaper includes blowers, heat exchangers, press shaping mechanism etc. Noodle Cake Dryer :

1. There are 2 kinds of Dryer: KHD horizontal running dryer and KVD Vertical running Dryer.

2. No pollution due to the friction between chain & guide as the KVD Dryer without guide.

3. It can sectional control the temperature of dryer by the auto temperature control devices.

Optional equipment Rice whitener, Rice color sorter, Auto synchronous operation system including PLC, center control panel, touch screen etc.

Copyright © Guangzhou Kennyway Food Processing Machinery Co.,Ltd. All rights reserved.

粤ICP备15020273号-1