参数

- Description

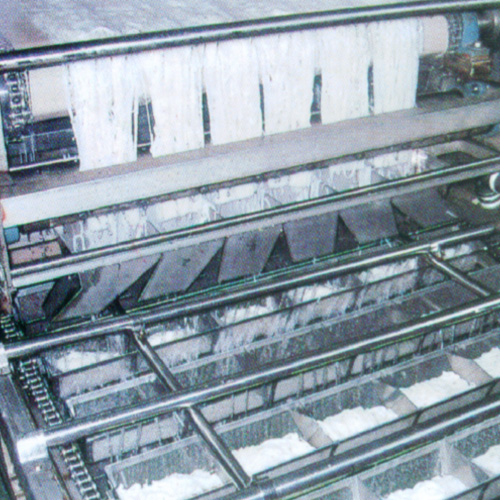

Different kinds of fresh noodles can be made from rice, corn starch, wheat starch, potato starch and tapioca etc. After sterillization, the preservation period of the fresh noodle may extend to 6 months.

The Flow chart of Fresh Rice noodle process:

Rice→elevating by jet flow→sand separating→soaking(fermentation)→washing→dehydrating→grinding→rice sheet steaming→anti-aging→sticks extruding→vermicelli extruding→cooking in lanes→vermicelli steaming→quantitave cutting→water cooling→PH value keeping→auto dividing→packing→sterillization→storage→inspecting→product

Technical Data:

| Type | Capacity(T/8H) | Total power(Kw) | Production Area(M2) | Steam consumption (Kg/H) |

| KR7-25 | 2.5 | ≈40 | ≈400 | ≈500 |

| KR7-40 | 4.0 | ≈50 | ≈500 | ≈750 |

| KR7-60 | 6.0 | ≈60 | ≈600 | ≈900 |

| KR7-80 | 8.0 | ≈70 | ≈700 | ≈1000 |

Non-standard food processing machinery--A strong point of Kennyway!

There are different kinds of non-standart equipments including noodle cake dryer, stick noodle dryer, mixer, steamer, extruder, elevator, conveyor, fryer, slitter, cooling machine, rice grinder made of SUS 304……etc.

Auto Press Shaper of noodle cake is an original patented product of Kennyway. Patent No.: ZL03209045.5.

△It is possible to pack the noodle cake by automatic packing machine after press shaping.

-

-

版权所有(C)广州市健力食品机械有限公司

粤ICP备2022125144号-1